Predictive Analytics in Supply Chain: Building Efficiency, Resilience, and Smarter Operations

Helen Barkouskaya

.7 min read

.2 September, 2025

Head of Partnerships

.7 min read

.2 September, 2025

What Does Predictive Analytics Really Mean for a Logistics Business?

If you run a logistics business, you already know how messy supply chains can get. Rates change overnight, weather disrupts routes, suppliers miss deadlines, and suddenly your carefully planned schedule is out the window. For years, most teams have tried to keep up with static forecasts, endless spreadsheets, and a lot of firefighting after the fact. The problem? By the time you react, the damage is already done - lost margins, unhappy customers, missed opportunities.

That’s where predictive analytics in logistics is making a real difference. Instead of waiting for disruptions to hit, companies are starting to use machine learning, statistical models, and live data feeds to see problems before they happen. Think of it less like shuffling yesterday’s reports, and more like running operations with a live radar that shows what’s about to change.

What does this look like in practice for a freight forwarder or a 3PL? It could mean spotting a demand surge weeks before peak season, predicting which overseas agent is likely to send incomplete rate sheets, or flagging containers that are at high risk of delay at port. For carriers, it could mean optimizing routes in real time to cut fuel costs and avoid congestion.

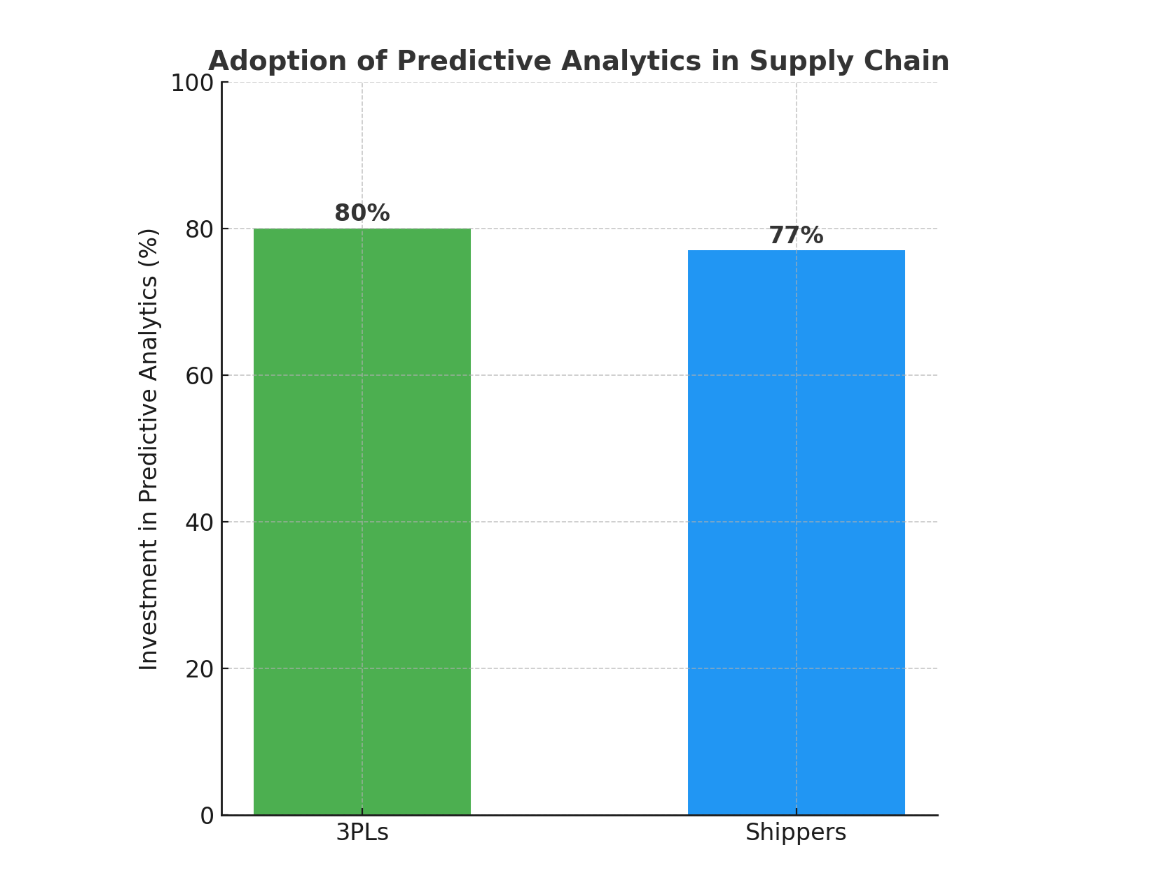

And the industry is catching on - 80% of 3PLs and 77% of shippers are already investing in predictive analytics to turn data into a competitive advantage (State of Logistics Report). Because in a business where margins are thin and volatility is the norm, being proactive isn’t just nice to have - it’s survival.

Key Benefits of Using Predictive Analytics in Supply Chain Management

So, what do logistics and supply chain companies actually get out of predictive analytics? The short answer: fewer surprises, lower costs, and happier customers. The longer answer-well, let’s break it down.

1. Better Visibility

Most logistics headaches start with blind spots. Predictive analytics changes that by giving end-to-end visibility-from procurement through to last-mile delivery. It doesn’t just tell you where things are; it highlights inefficiencies and points out where you can save time or money.

2. Smarter Decision-Making

Gut instinct has its place, but when margins are tight, data-driven decisions win. Predictive models help with inventory planning, demand forecasting, and logistics scheduling-meaning fewer misses, fewer “we didn’t see that coming” moments, and better profitability.

3. Real Cost Savings

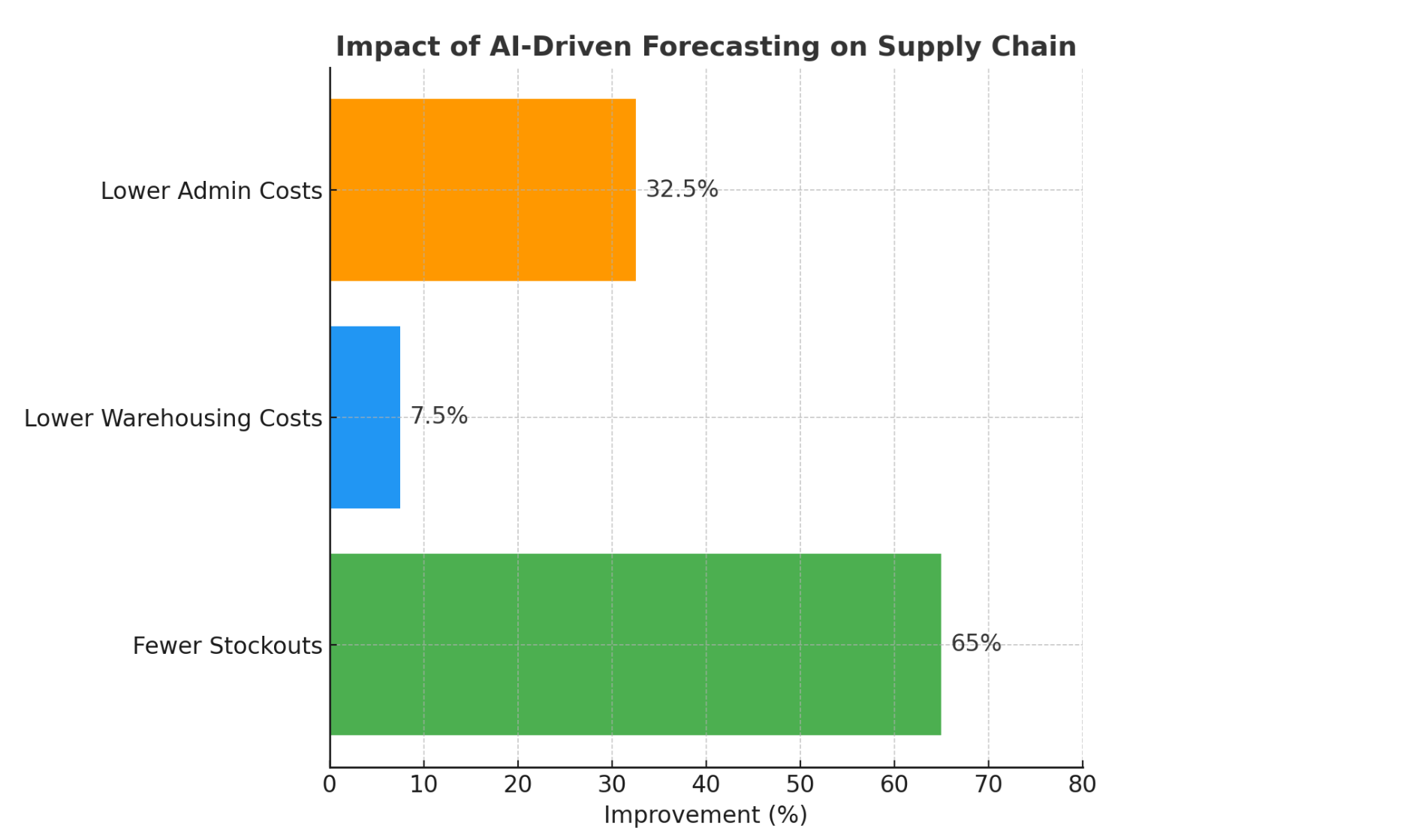

This is where it gets very real. AI-driven forecasting can cut forecast errors by 20–50%, which translates to up to 65% fewer stockouts, 5–10% lower warehousing costs, and 25–40% lower admin costs (McKinsey). UPS has already proven this at scale-its predictive routing system (ORION) saves an estimated $100–200 million a year just by shaving unnecessary miles off delivery routes (Transmetrics). It’s a prime example of AI in supply chain management, where predictive routing directly drives measurable savings.

4. Happier Customers

At the end of the day, supply chains are judged on reliability. Predictive analytics makes sure the right product arrives at the right time, every time. More accurate forecasting and smoother logistics mean fewer late deliveries-and customers notice.

5. Stronger Risk Management

Disruptions will always happen, but predictive analytics gives you early warning. It can flag risky suppliers, highlight potential delays, or even suggest rerouting shipments before problems escalate. That ability to be proactive instead of reactive is what turns resilience into a competitive advantage.

And here’s the kicker: nearly 50% of supply chain leaders already report ROI from AI, with logistics and transportation seeing the biggest early gains (The SCXchange).

How Predictive Analytics Improves Supply Chain Resilience

In logistics, resilience isn’t just about bouncing back from disruption - it’s about staying ahead of it. Predictive analytics gives supply chains that extra layer of foresight, helping businesses stay steady even when things get messy.

Spotting trouble early – Whether it’s a supplier falling behind, a shipment stuck at a port, or raw materials running short, predictive analytics picks up the signals before they become full-blown problems.

Running “what-if” drills – By modeling scenarios like strikes, weather delays, or demand surges, managers can see the impact and line up backup plans.

Smarter supplier choices – With predictive risk scoring, companies can evaluate suppliers more objectively and reduce dependence on those most likely to fail.

From firefighting to prevention – By blending structured data (like ERP logs) with unstructured data (like weather reports or news), companies shift from reacting in crisis mode to preventing issues in the first place.

How Predictive Analytics Improves Supply Chain Efficiency

Resilience is one side of the coin - efficiency is the other. Predictive analytics helps supply chains cut waste, speed things up, and use resources more wisely.

Sharper demand forecasting – with modern supply chain forecasting tools, companies face fewer stockouts, less overstocking, and inventory that actually matches customer needs.

Lean inventory management – Predicting the right stock levels for the right location lowers carrying costs and avoids tying up cash in the wrong places.

Smarter transport and logistics – Route and shipment planning powered by predictive models accounts for fuel costs, traffic, and delivery constraints, squeezing more value from every mile.

Better resource use – Warehouses, fleets, and staff are allocated where they’re needed most, reducing idle time and bottlenecks.

Predictive maintenance – Machines and vehicles don’t just break down anymore - predictive models flag issues in advance so downtime is minimized.

The bottom line? Supply chains get faster, leaner, and more reliable - all while keeping customers happier.

Use Cases of Supply Chain Predictive Analytics

Far from being hype, predictive analytics logistics solutions are already at work, helping companies streamline shipments, strengthen partner networks, and cut avoidable costs. Here are the areas seeing the clearest wins:

Demand forecasting that actually works – Logistics teams can tap into seasonal trends, promotions, and external market signals to anticipate shipping volumes more accurately and avoid costly surprises.

Smarter inventory placement – Instead of piling up safety stock “just in case,” predictive models guide where to position inventory across warehouses and hubs so goods are closer to demand.

Dynamic pricing and freight rates – Borrowing tactics from Amazon and airlines, logistics players can use forecasts to fine-tune prices, boosting margins while staying competitive. Take a look at how Whitefox built a smarter freight quoting solution - and the real results it delivered for customers.

Route and fleet optimization – UPS has shown the power here: predictive routing can cut millions in fuel and labor costs by rethinking how and when trucks move. Case in point: UPS’s ORION platform is estimated to save $100–200M annually by optimizing delivery routes.

Better supplier and partner performance tracking – By analyzing on-time rates, defect ratios, and compliance history, logistics firms can prioritize the partners who consistently deliver.

Predictive maintenance for fleets and equipment – IoT sensors feed data into models that predict breakdowns before they happen, slashing downtime and keeping operations running smoothly.

In short: predictive analytics turns logistics from reactive guesswork into a proactive, data-driven engine.

Real-World Examples of Predictive Analytics in Action

Walmart

Walmart isn’t just using predictive analytics to stay stocked-it’s using it to own the customer journey. The team analyzes millions of online searches, purchases, and browsing behaviors to forecast demand more accurately. That means the right products are ready in-store and online, making surprises less common and satisfaction more frequent.(Newcastlesys)UPS

You know that feeling when every mile your truck drives counts? UPS does. Their ORION system recalculates routes in real time, slicing fuel usage, miles driven, and labor costs-by the hundreds of millions of dollars. Predictive routing isn’t just smart; it’s hugely impactful.(TransmetricsThroughPut Inc.Business Insider)DHL & Maersk

These global giants aren’t sitting still. DHL’s “MySupplyChain” platform stitches together digital visibility, predictive demand patterns, and workflow automation into a supply chain “brainsystem” that adapts in real time. Maersk, meanwhile, uses predictive analytics to forecast ship and container movements-helping them reposition assets and save millions.(Transmetrics)Western Digital

When COVID-19 hit, Western Digital used its predictive risk engine to sidestep supply chain collapse. Rather than scrambling in panic, the company had the power to foresee and adjust-saving both dollars and customer trust. (Newcastlesys.com)Panama Canal

This one’s out of left field-but powerful. When droughts and protests slowed traffic through the Panama Canal, predictive analytics allowed experts-and their customers-to anticipate delays and reroute or reschedule proactively. That kind of foresight makes a dent when the biggest channel in world trade is stuck.(Transmetrics)Optym + Greyhound (DriverMAX)

In the U.S., Optym powered a tool called DriverMAX for Greyhound. Within an hour, it generates efficient routes for over 1,000 drivers. The result? Reduced operations costs by millions and happier drivers with smarter schedules.(Wikipedia)

Challenges in Implementing Predictive Analytics

The upside is obvious, but getting there isn’t friction-free. Here’s where companies usually stumble:

Messy or incomplete data – if the input is wrong, the forecasts won’t be worth much.

Old systems that don’t play nice – legacy ERPs and warehouse tools weren’t built for advanced analytics.

Shortage of skilled talent – data scientists and supply chain analysts are in high demand (and hard to keep).

Privacy and security concerns – suppliers’ rates and customer data need strong protection.

Change resistance – teams must learn to trust the models instead of just relying on gut feel.

At the end of the day, overcoming these challenges often requires logistics software solutions tailored specifically for your operations - systems that can integrate data, scale with your operations, and deliver insights your teams can act on. That’s where working with a trusted provider can make the difference.

Best Practices That Work

The companies who win with predictive analytics usually follow a few golden rules:

Set clear targets – e.g., “cut stockouts by 20%” instead of vague “improve forecasting.”

Invest in data plumbing – build a single source of truth by unifying ERP, WMS, and logistics feeds.

Choose the right tools – AI/ML platforms that scale and integrate with your existing stack.

Form cross-functional squads – pair supply chain managers with data pros for real impact.

Start small, then scale – pilot one lane or product line, prove ROI, and grow from there.

And one more: pick a trusted software development partner. Predictive analytics isn’t plug-and-play; it takes custom integration and deep logistics knowledge. Working with a team that’s built these solutions before can save you from costly missteps and get you to value faster.

What’s Next for Supply Chain Predictive Analytics

The horizon is moving fast. Expect to see:

Smarter AI and ML – the next wave of AI in supply chain management, with algorithms that adapt in real time as conditions shift.

IoT-driven visibility – sensors giving live updates on shipments and assets.

Blockchain tie-ins – trusted, transparent data across partners and borders.

Prescriptive and cognitive analytics – moving beyond “what might happen” to “what action should we take.”

Wrapping It Up

Predictive analytics isn’t a shiny add-on anymore-it’s becoming table stakes for resilience, efficiency, and customer trust. By spotting risks early, forecasting demand with accuracy, and streamlining operations, companies build supply chains that don’t just survive disruptions-they adapt and thrive.

For logistics providers, manufacturers, and retailers, the message is simple: the sooner you adopt predictive analytics, the sooner you future-proof your operations.

Ready to see what predictive analytics could do

for your logistics operations?

Let’s talk about building smarter forecasting, leaner routes, and systems

that actually keep up with real-world complexity.